Titanium is an extremely versatile metal that has secured its place in the aerospace industry as well as medical, chemical, military and sporting goods. Titanium, in any form, was rarely used prior to World War II due to the difficult and expensive process of isolation and production. Once an economical method of production was developed, the first major use of titanium was for military aircraft and submarines beginning in the 1940’s. By the early 1960’s, commercial aircraft manufacturers began using titanium alloys as well.

Alloys containing titanium are known for their high strength, lightweight and corrosion resistance. For example, titanium is as strong as steel but is about 40% lighter in weight. This is ideal for use when strength to weight ratios are extremely important like aerospace. Titanium is also non-magnetic and biocompatible (non-toxic, non-allergenic) making it an ideal choice for a wide variety of medical uses.

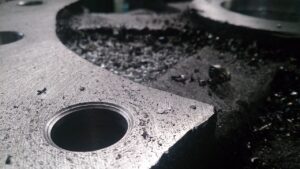

Scrap titanium comes from two main sources that are classified as new and old scrap. New titanium scrap comes from the production and fabrication of titanium components. Old scrap is recovered and recycled from used components like aircraft parts, heat exchangers, armor plating, medical devices, bicycle frames and many more. Coveted for its strength to density ratio, titanium is a valuable recyclable. When it comes to making recycling easy and efficient for your business, let Consolidated Resources, Inc. handle it all. We provide comprehensive recycling solutions for all your industrial and commercial recycling needs.