The metal recycling process has quite a few steps. Industrial businesses in Phoenix understand that these steps are incredibly important for the environment, the price point of their products, and to help boost the economy. So how is metal recycled exactly?

Sorting and Processing Industrial Scrap

The metals are collected from businesses and/or individuals and then they go on to sorting. The recyclable metals need to be separated from the non-recyclable metals. The type of metal is also very important. The quality of the pieces determines where it goes next. The metals go through a quality check sticking to a general rule that a product needs to be 50% or more made of metal. In some cases, the metal parts can be removed from other materials, such as plastics so they can go to their specified areas to be recycled. Magnets can help determine what kind of metals are coming into the facility. For instance, ferrous metals (containing iron, like steel) stick to a magnet, and nonferrous (all other types) will not. The use of more advanced machines such as infra-red scanning and x-rays is also really popular for sorting. They help to improve the rates of metal recovery during the sorting process.

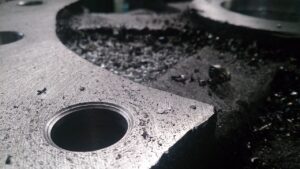

Shredding Scrap Metal

After the metals go through the sorting process, the pieces need to be compacted so there isn’t much space taken up on conveyor belts going forward. After the metal is compacted, it will go through a shredding process. This is where the compressed objects are broken down even further into very small pieces. It takes less energy to melt down the small pieces since they have a large surface-to-volume ratio. Steel tends to get formed into blocks and aluminum goes into sheet formations.

Melting the Metal

After shredding and changing the formation of the metals, the objects are put into a large furnace. Depending on the properties of the metals going in, there will be a specific furnace designed for each metal’s make-up. Even though this process uses a good amount of energy, it doesn’t even compare to the amount used to create new metals from raw ore.

The Scrap Metal Purification Process

Now the metals go into a purification process. In order to keep the high-quality metal which is free of impurities, this process is crucial. Many different methods can be used for this, including electrolysis.

Solidifying Molten Metal

After the purification process is complete, the metals, which are now molten, go through a cooling chamber which solidifies the metal. Chemicals are added during this time for density purposes as well. Once solid, the metals are free to be used over again for brand new products.

Learn more about Recycling Industrial Scrap Metal

CRI is Phoenix’s Trusted Industrial Metal Recycler

We can help you maximize the value of your scrap. Contact us to learn more.